Mechanical, Electrical, and Plumbing (MEP) Engineering refers to various characteristics of building design. It consists of planning, designing, and maintaining the MEP systems of a building. MEP systems act as the central nervous system of the building and are responsible for adding the “human comfort” features in a building. They also assist in cost management, construction administration, documentation, maintenance, building operation, and renovation as well.

Smart decisions at the design stage could greatly reduce the building costs, and create a much better and suitable environment for the occupants. For real estate developers, a building with well designed MEP systems can grant a competitive advantage when it comes to renting or selling building spaces. One of the important things to keep in mind while designing a building’s MEP system is that the design must meet all the building codes required by the local government.

Energy efficiency becomes extremely important when the energy bills start rising. Once a building is operational, energy bills like electricity, gas, and water bills become a permanent monthly expense. In commercial buildings and industrial buildings, these numbers can go up to 6 figures per month. However, with the help of MEP engineers, a well-designed MEP system working at optimal performance can greatly reduce energy bills, reduce energy wastage, and even add features that promote energy saving. This ultimately leads to potentially saving thousands per month.

Optimal building performance is extremely important, but most building owners want reasonable costs. However, poorly planned MEP design will ultimately lead to cost rising sharply due to poor layout, improper insulation, wiring, etc. In some cases, this can also lead to a change order, which will add delay and impose unnecessary costs.

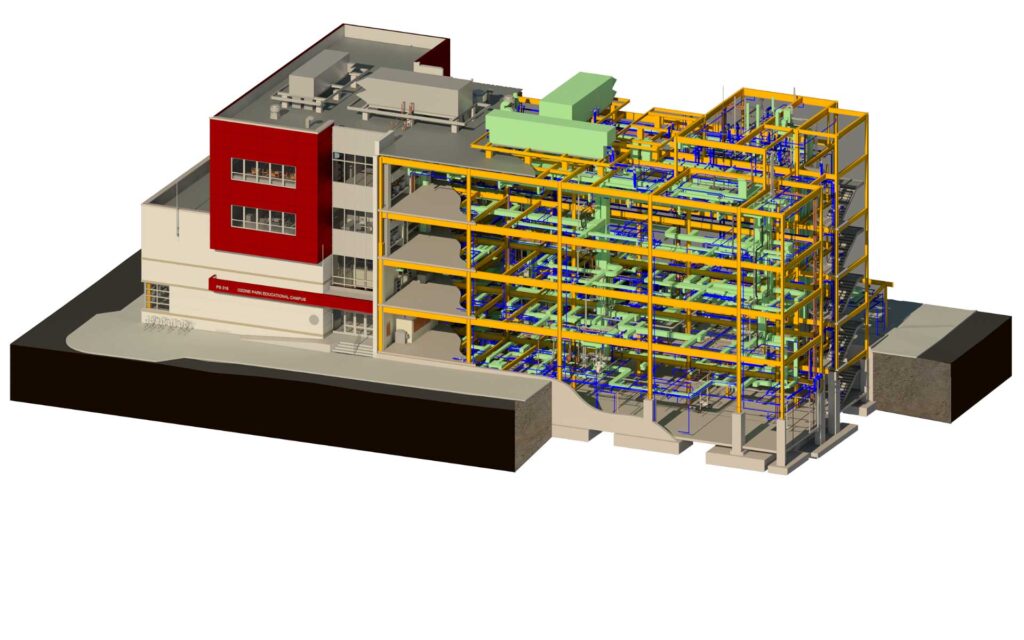

Building Information Modeling (BIM) is a powerful tool for detecting component clash, preventing change orders, and effectively designing the building system layout in the design stage. MEP engineers are able to design the system layout and install them using the least materials and man-hours, without compromising performance. This is hard to accomplish with traditional 2D drawings, especially in areas where the component layout in densely populated.

Water conservation, energy efficiency, and an optimal layout can greatly reduce ownership costs. However, design engineers must also consider the construction stage when modeling the project. Conflicts that involve locations and specifications are evident, but there are also conflicts that affect the workflow.

Architects and Engineers must make sure that layouts and installation details are practical for contractors, considering how workers will deploy equipment and materials. A good design also considers that there are many subcontractors involved, and construction documents have clear instructions to reduce interference.

A good building design not only simplifies construction but also maintenance and renovation. Equipment and components installed must be accessible for routine inspections and part replacements when required. Building design must also consider the replacement of large equipment, and the layout must ensure this is possible. For instance, a building may need high-efficiency boilers and chiller in 10 years.

A digital twin, in such cases, proves to be a powerful tool for building maintenance as it creates a replica of the actual conditions of all the MEP systems in the building. This is very useful for tracking component wear, and for planning maintenance tasks.